Your cart is currently empty!

Recycling plastic waste into building materials, electric, gasoline and diesel

Today, environmental pollution is no longer a problem of individual countries but requires global cooperation. Among them, plastic and nylon waste is one of the main causes of worsening pollution. For this reason, we have conducted research on how to recycle this type of waste.

Decomposition Timelines:

While exact figures can vary, here are some general estimates for the decomposition time of common plastic items:

1. Plastic bags and bottles: 450-1,000 years.

2. Styrofoam cups: 500 years.

3. Fishing line: 600 years.

4. Plastic utensils: 100-500 years.

The Impact on the Environment:

1. Landfill accumulation: Landfills become overwhelmed with plastic waste, reducing their lifespan.

2. Marine pollution: Plastics and microplastics end up in oceans, harming marine life.

3. Soil contamination: Plastic fragments can leach harmful chemicals into the soil.

4. Air pollution: Burning plastics releases toxic gases into the atmosphe.

Our solutions:

As we know, the origin of plastic and nylon waste comes from petroleum. Therefore, we can completely reverse the process to recycle this type of waste.

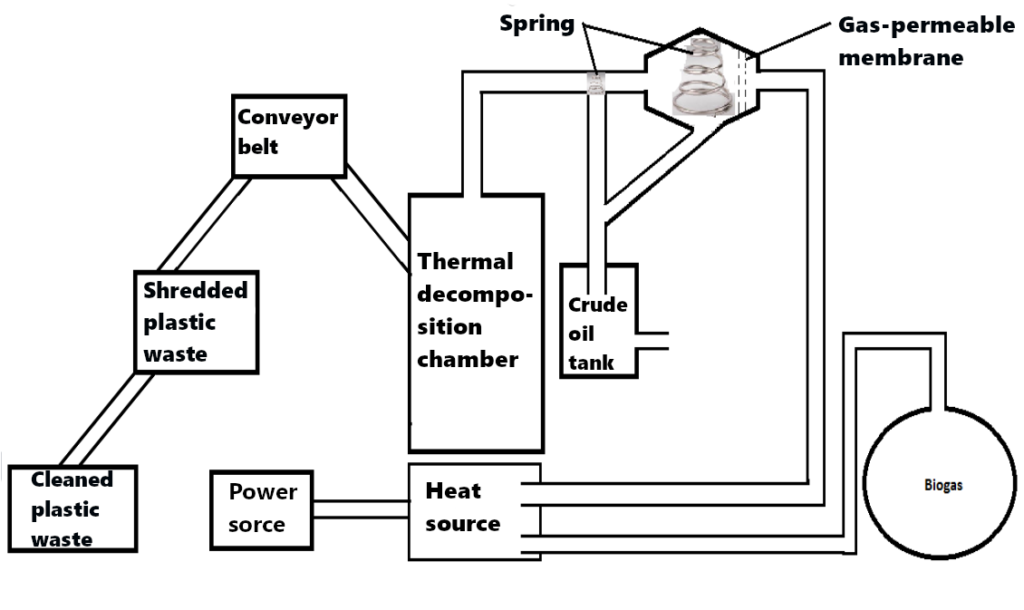

Principle of operation diagram:

Principle of operation:

– Plastic and nylon waste are cleaned, shredded, and transported via a conveyor belt into the combustion chamber. The heat source for combustion comes from electricity or biogas tanks. After the pyrolysis process, petroleum vapor is collected and then condensed into petroleum in wax form. Naturally, this wax-like petroleum contains many impurities, and to transform it into gasoline or diesel, it must go through another complex process. The process of recycling plastic and nylon waste into gasoline and diesel will be presented in detail in another technical report. This will explain how impurities can be completely removed to obtain the highest quality gasoline and diesel, ensuring that internal combustion engines are not adversely affected.

– The excess vapor generated during the pyrolysis process is a highly combustible vapor with a high calorific value. This vapor can be recycled as a heat source for the pyrolysis process or directed to a thermal power plant to generate electricity.

– At the conclusion of the pyrolysis process for plastic and nylon waste, we obtain a mixture of residues within the pyrolysis reactor. By combining this residue with cement, we can produce a concrete block with remarkable hardness, significantly surpassing that of conventional concrete. Surprisingly, this concrete block is also exceptionally lightweight compared to other concrete blocks of the same size. In fact, it is buoyant enough to float on water. The specific mixing ratios, procedures, and technologies used to create this material will be detailed in a separate scientific paper.

In summary, waste is extremely hazardous, yet it is an essential part of our daily lives. While its use is unavoidable, we can mitigate its negative impacts by effectively utilizing and recycling it. Not only does this protect the environment, but it can also generate significant economic benefits.

If you require any further information regarding this project, please do not hesitate to contact us via email at admin@evcarglobal.com.